Sprinkler Warehouse Presents

Sprinkler Guides

VIDEOS

Search the video library to learn best practices, quick fixes, and seasonal sprinkler adjustments.

INSTALL

Step-by-step instructions on how to install a sprinkler system from start to finish.

OPERATE

Learn about operating different sprinkler system brands and their components.

REPAIR

DIY sprinkler system repair to save money and keep your irrigation running smoothly.

Make Your Yard A

Just purchased a home? At Sprinkler Warehouse we know how important your yard can be for memory making. This sprinkler guide aims to help new homeowners understand, learn and troubleshoot irrigation systems to make your yard an extension of your home.

Need A Place To

Start?

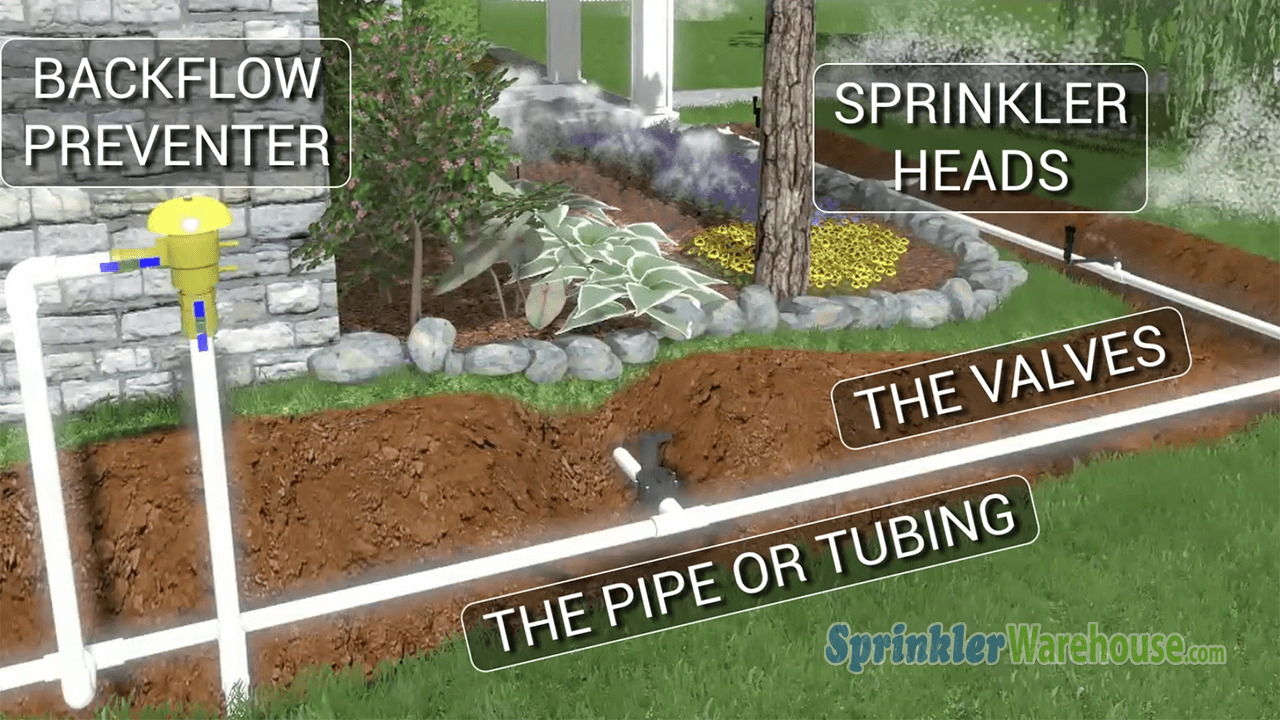

Anatomy Of A Sprinkler System

Discover The Parts Of A Sprinkler System Today I’m talking about the basic parts of the sprinkler system. …

Sprinkler System Install: An Overview Of The Process

How To Design & Install A Sprinkler System Hey Irri-Gators, we’re at the home of one of our …

How To Repair Your Febco 765-1 PVB

Everything You Need To Know About Fixing Your Febco PVB Have you ever woken up on a wintry …

Residential Or Light Commercial Controller

How To Choose A Residential Or Light Commercial Controller Which Hunter Controller Is Right For Your Irrigation System? …

Determining GPM

Steps On How To Find Gallons Per Minute (GPM) Sprinkler systems can be traced back to3000 BC when …

Designing An Irrigation System

Best Practices in the First Step of the Irrigation Process This article discusses how to design an irrigation …

Troubleshooting Valve Issues

Troubleshoot Irrigation Valve Issues So one of your zones won’t come on, or won’t turn off. How do …

How To Dig & Run Pipe Under A Driveway Or Sidewalk

Running Pipe Under Concrete This article explains how to dig and run a pipe under an obstacle such …

Installation Guide For Narrow Planting Beds Near A Structure

Designing Drip Irrigation Layout For Narrow Landscape This article is an installation guide for narrow planting beds near …

Improve Your

Outdoor Space

At Sprinkler School, we believe there’s always room for improvement. The more you learn, the more you grow and that applies to your yard as well! Create the outdoor oasis that you’re proud of with our sprinkler guides and tutorials.

Featured Product

Upgrades!

FEATURED PRODUCT

K-Rain ProPlus Rotor

The ProPlus adjustable arc and full-circle gear-driven rotor come standard with nine numerically coded interchangeable nozzles. The flagship model in the PRO Series line, the ProPlus is packed with features that ensure reliability, saving the installer time, money, and needless frustration. Excellent nozzle performance delivers an exceptional fall out of the pattern. In independent testing by C.I.T., the ProPlus delivered up to 90% uniform coverage.

FEATURED PRODUCT

K-Rain ProSeries 150 In-Line Valve 1 in. FPT | 7101

K-Rain’s ProSeries 150 Valves offer the irrigation professional a wide array of features and benefits. The 1″ valve has a removable metering pin and external bleed screw promoting easy maintenance and manual operation. The 1″ valve provides the professional easy servicing access without removing the valve from the system.

FEATURED PRODUCT

K-Rain PRO-LC 4 Station Indoor/Outdoor Controller

Available in fixed 4, 8, and 12 station indoor and outdoor models, the K-Rain Pro-LC is a compact controller with an array of user-friendly features: easy-to-follow programming, a full program screen display showing watering days, start times, number of stations, and special programming, as well as rain/freeze sensor compatibility, seasonal adjust for water conservation and a buried valve locator for easy maintenance and more.